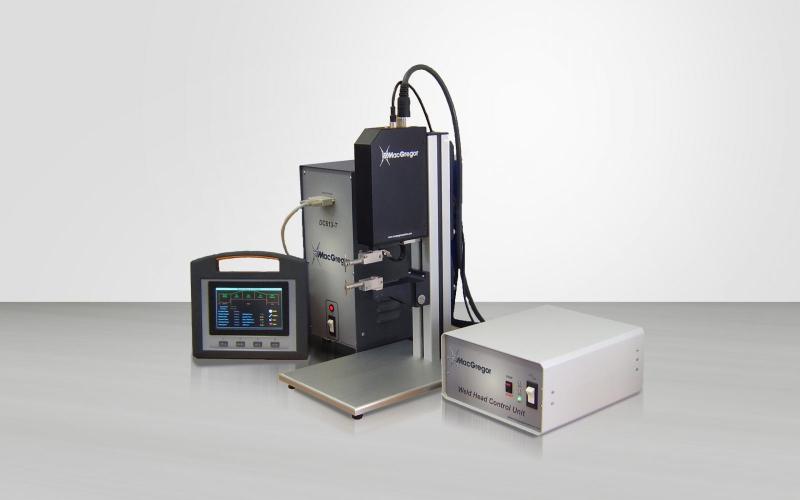

LH Series - Precision Weld Heads

The LH series of precision servo weld heads combine the latest ultra low friction, high speed actuation technology with cutting edge control electronics to deliver fully integrated process programmable spot welding with real time displacement monitoring and process control. LH Series weld heads fully integrate with the MacGregor SMART series of power supplies to deliver a precision fully featured welding process definition and data collection system suitable for both high end manual or automatic spot welding assembly. All SMART series power supplies and heads provide true servo driven output control that is derived from precision calibrated sensors. Furthermore, to meet the increasing demands from the automotive, medical and aerospace sectors, secondary sensors and feedback methods assure system integrity and accuracy on a weld by weld basis. Standard options include 1µm weld displacement encoder with real time trace and windowing capability with 25mm or 100mm travel models.

Key Features:

- Fully programmable motion profiles

- 0.1N force resolution, 1% accuracy

- Automatic or manual mode operation

- Ethernet control & programmability

- Integrated control with weld schedules

- Displacement monitoring

TECHNICAL DATA

| Model |

LH-90-A |

LH-180-A |

| Minimum force |

7N |

8N |

| Maximum force |

90N |

180N |

| Maximum speed |

400mm/s |

400mm/s |

| Force accuracy |

0.3N |

0.6N |

| Force repeatability |

0.3N |

0.6N |

| Duty cycle |

5% @ max force |

3% @ max force |

| Current handling |

3000A |

3000A |

| MECHANICAL FEATURES |

|

|

| Stroke |

25mm |

25mm |

| Actuation |

Auto or manual foot pedal |

Auto or manual foot pedal |

| Weight |

11.2 kg |

11.2 kg |

| Positional accuracy |

+/- 1µm |

+/- 1µm |

| Options |

100mm stroke variant |

100mm stroke variant |

| Stroke |

+/- 1µm encoder standard |

+/- 1µm encoder standard |