Four control types to select from You can select four control types

"secondary constant current",

"constant current",

"constant power", and

"combination of constant voltage and current", which makes the

optimum welding conditions possible.

Communication function standard RS-232C/RS-485 (selectable) communications make it possible to set and monitor the

welding settings from an external device such as PC.

Transformer switching function Five welding machines can be controlled with one power supply by connecting an

external transformer switch.

Supports 3-phase 200V and 400V welding power supplies The welding transformer supports power supplies worldwide with 3-phase 200 to 240V

or 380 to 480V (set at factory).

Power stop function A constant fusing penetration is made possible by the optional displacement monitor function.

Fast rise in welding current Since the welding current rises 6 times faster than for previous welders, it is even possible

to weld micro work pieces in a short period of time.

Maximum welding current 6000ABecause of the fast current rise, this power supply supports short-time/large-current welding

applications.

Reduced welding current ripple Current ripple is reduce to 1/3 of that for previous models. For the same effective current,

the peak current is smaller than for previous models.

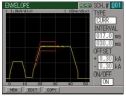

Envelope function

With this function, the actual waveform can be judged good/bad by comparing with the "envelope" waveform, which defines the acceptable range. The envelope waveform can be created based on the standard waveform (average welding waveform) or on the monitored real waveform.